A DraftSight Case Study: Bill’s Custom Fab, Inc.

Bill’s Custom Fab, Inc. has provided custom design and fabrication services for creating structural steel components for a range of diverse applications since 1990.

Bill’s Custom Fab, Inc. has provided custom design and fabrication services for creating structural steel components for a range of diverse applications since 1990.

Over the years, the family-owned and operated business has worked with a wide variety of clientele, allowing the fabrication shop to expand its knowledge, experience, and expertise into many industries, ranging from construction and heavy-machine clients to residential and walk-in customers.

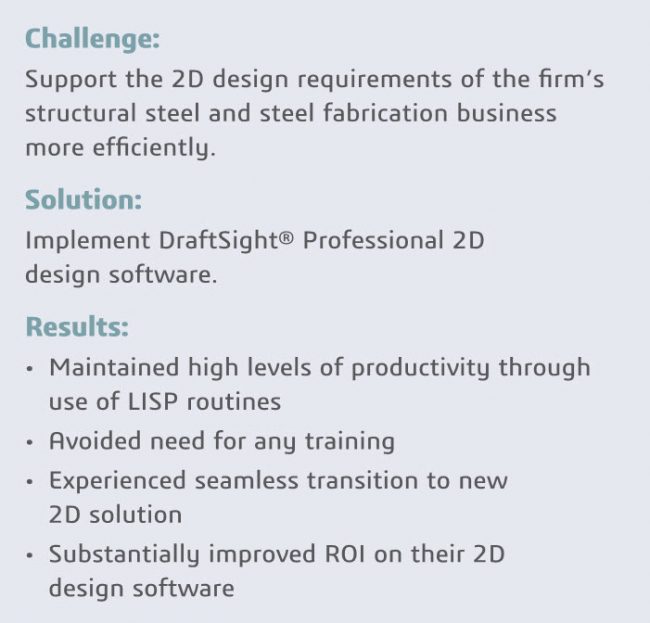

The firm uses 2D CAD for fabrication of structural steel—such as steel beams for construction, tubular steel for handrails, and steel channels for stair stringers. The company periodically re-evaluates its design and fabrication tools with an eye toward increasing efficiency, boosting productivity, or adding capabilities. Licensing changes with its former CAD provider led the company to re-evaluate its 2D design solution.

According to Estimator David Yerks, “I had used my previous CAD for 30 years, but licensing changes made it time to look for another solution,” Yerks recalls. “We looked at a bunch of CAD systems, including one which specializes in steel construction, but they were going to require a greater IT investment. I had used DraftSight software previously and had noticed the enhancements with each release. That’s why I suggested it as our next 2D solution.”

“DraftSight gives us all the 2D functionality and professional tools we need, doesn’t require training because it operates just like our legacy CAD, and supports profitability. By moving to DraftSight Professional, we are substantially improving the ROI for our CAD investment.” – David Yerks

In addition to functionality and ROI, the deciding factor in Bill’s Custom Fab’s move to DraftSight Professional was the solution’s stability, data compatibility with major CAD formats (including DWG and DXF™ files), and ability to run LISP macros and routines, which the firm leverages to create common structural steel features.

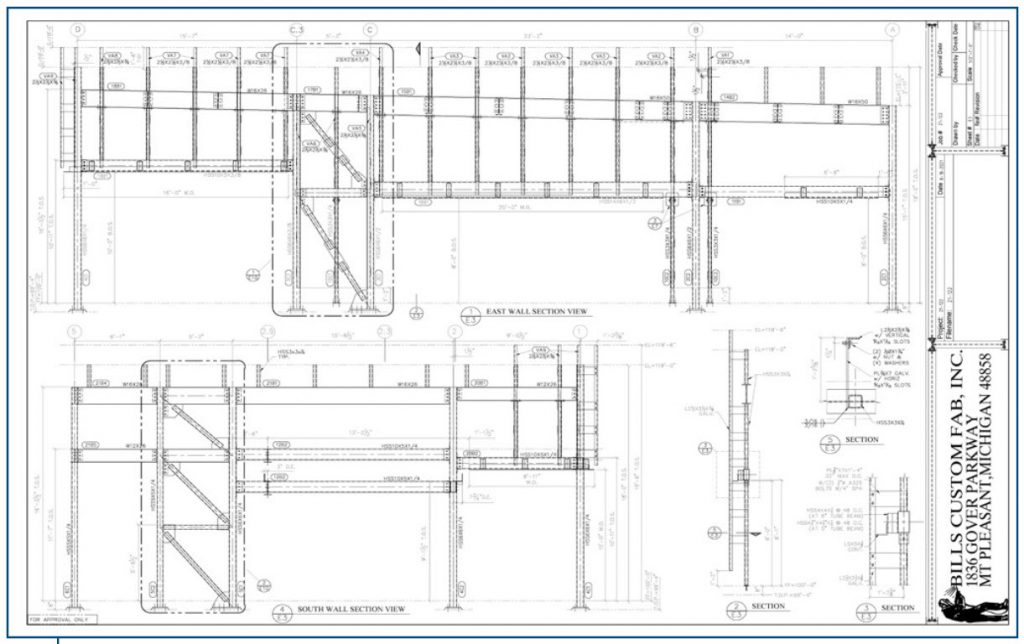

“We use DraftSight for structural steel fabrication and erection drawings, custom fabrication shop drawings, and also use the DXF features for our plasma cutting table,” Yerks says. “With so much capability, it’s just the right choice for our growing company at the moment.”

Seamless Transition with Data Compatibility

The company’s transition to DraftSight Professional software was seamless—with no downtime or training requirements—because DraftSight’s user interface and capabilities are similar to its legacy CAD. “With DraftSight Professional, we can do everything that we used to do, with an improved ROI,” Yerks stresses.

“We can open all of our legacy 2D CAD drawings, as well as 2D building drawings that we receive from architects and structural engineers,” Yerks adds. “On those projects, we create our drawings based on the information contained in the building drawings, such as beam and column locations and anchor bolt placements. We create the structural steel plan views and elevation views in DraftSight, which the field crews used to put the steel structure together.”

Lisp Routines Drive Productivity

Another important benefit from moving to DraftSight Professional is the ability to continue to use LISP language macros and routines in DraftSight, maintaining efficiency and productivity via continued use of automated commands while reducing costs.

“Over the years, we’ve developed a large number of LISP routines for automating the creation of drawings for structural steel shapes,” Yerks explains. “We simply input the type of structural steel (e.g., I-beam, tubular steel), the sizes, weight per foot, and bolting patterns, and the LISP routines automatically generate error-free drawings,” Yerks notes. “Being able to use LISP routines for easily creating drawings of structural components has not only been a very important factor in our use of DraftSight, but also the key feature underlying our decision to move to DraftSight.”

Much More Than Structural Steel

Although much of Bill’s Custom Fab’s business revolves around structural steel, the company also uses DraftSight Professional to develop production drawings for other types of design work. For example, other projects have included developing planters, fire pits and rings, custom trailers, and a new ductwork system for a restaurant.

“We rebuilt an oil rig that was destroyed in a fire and even designed a custom trike for a customer who came to us with a 350 HP 2.4L ECOTEC engine and asked us to design and build a three-wheeled motorized vehicle that resembles the look of a Ferrari.” Yerks says.

“No matter what project we are working on, DraftSight Professional software is worth every penny that we pay for it because we continue to operate our shop efficiently and complete all of our different types of work just like we’ve always done, but with more efficiency.”

Summary

By transitioning to DraftSight Professional design software for creating structural steel fabrication designs, Bill’s Custom Fab has increased design efficiency and substantially improved its return on investment (ROI) in its 2D design software.

Switching to DraftSight was the smart choice for Bill’s Custom Fab. It very well may be the smart choice for you too. If you’d like to try it for yourself, here’s the good news: You can download the free 30-day trial and see for yourself. Just go here to get started: https://www.draftsight.com/freetrial. We think you’ll also find some compelling reasons to make switch to DraftSight.