Driving Innovation: How Knapheide Manufacturing Company Benefits from DraftSight’s 2D CAD Software

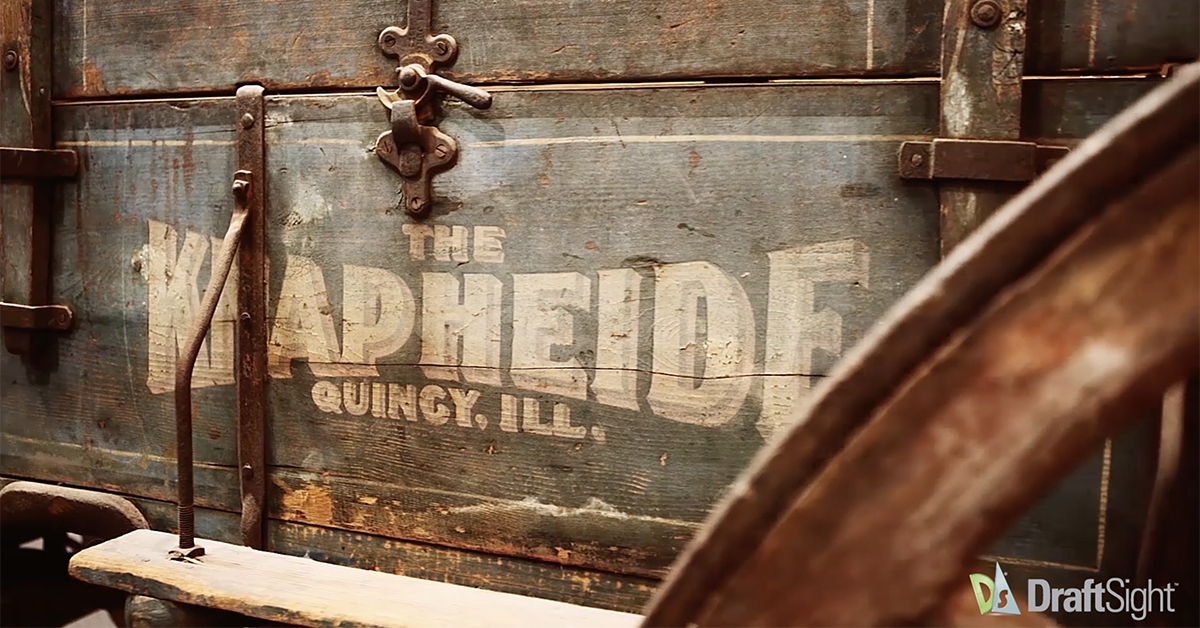

If you’re in the market for a commercial truck bed or truck accessories, you may have heard of Knapheide Manufacturing Company. Knapheide is a 175-year-old company that started as a wagon builder. In 1912, the third generation of the Knapheide family put a wooden wagon on a Ford Model T, which was a significant turning point for the company. The Knapheide family’s innovative approach to transportation has continued to drive the company’s success for over a century.

Based in the United States, Knapheide operates manufacturing facilities and distribution centers across the country. Its product line includes a wide range of truck bodies, from service/utility bodies to mechanics trucks and custom solutions. The company also offers fleet management services and aftermarket parts and accessories. With its commitment to sustainability and safety, Knapheide products are not only functional but also environmentally conscious.

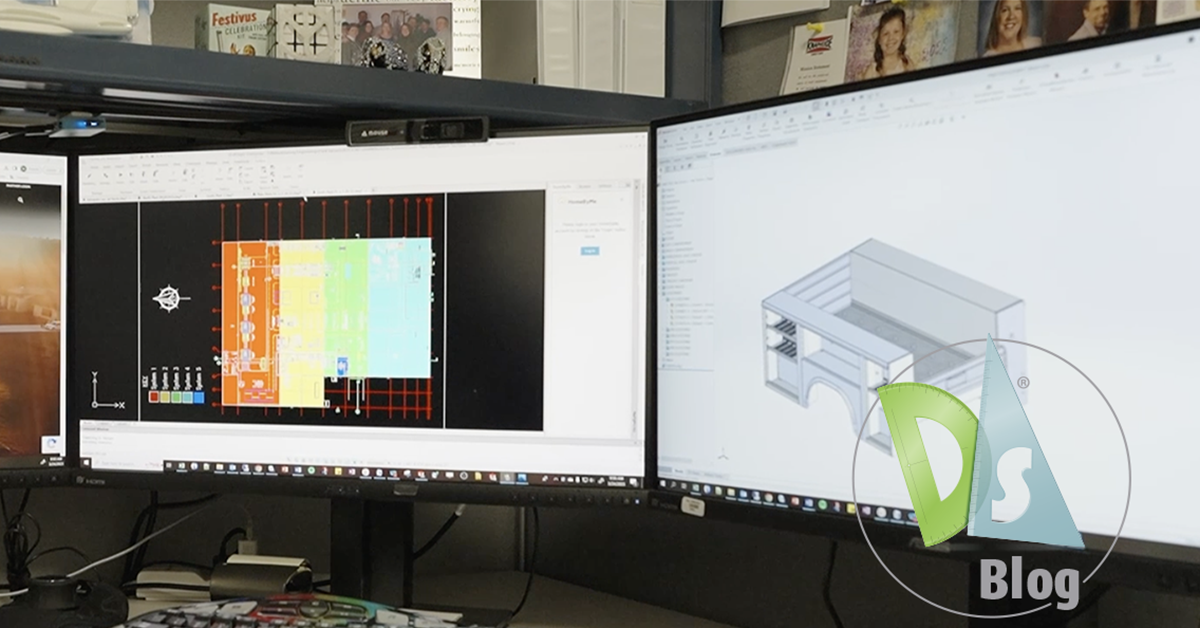

Knapheide Manufacturing Company uses DraftSight and SOLIDWORKS to support its manufacturing processes. We had a chance to connect with Martin Ohnemus, the PLM/CAD Administrator at Knapheide, at 3DEXPERIENCE World 2023 in Nashville to learn how DraftSight is benefiting Knapheide’s operations.

“We use DraftSight in a lot of areas, but one thing that I know it’s primarily used for is tool design. Our fabrication group, every time they’re designing a new tool, a lot of their vendors are working in 2D so this provides an opportunity to share data with them,” shared Ohnemus.

“We use SOLIDWORKS too, but DraftSight is very powerful. Sometimes you just need to do a quick layout, and DraftSight helps us provide a quick drawing to a customer, showing them a layout of maybe how the boxes will be on their on their bed. It gives them some ideas. And we use it for production…It allows us to change a standard product without having to pull all new part numbers. We can quickly do that in DraftSight and we get an amazing product built every time,” Ohnemus continued.

DraftSight allows Knapheide designers and engineers to create detailed 2D drawings of their truck bodies and other products. These drawings can be easily shared and modified, allowing for collaboration and feedback from customers and other team members. This can help to reduce errors and ensure that the final product meets Knapheide’s high standards.

“In our business we do a lot of sheet metal, so the sheet metal tools are my favorite. I’ve been fortunate to work on a number of customer designs, and I’m proud of each one,” detailed Ohnemus.

Unlike some of its competitors, DraftSight’s licensing model is cost-effective and sustainable, which allows Knapheide to use 20 licenses every day.

“That licensing model, a lot of the competitors don’t have that. A lot of them have gone away from network licenses and you now have to re-purchase the license every three years. It’s just not sustainable for companies and we are looking for a better solution. I think DraftSight provides that solution,” conveyed Ohnemus.

Ohnemus also shared how Knapheide benefits from its relationship with the DraftSight team, “It is a partnership, having the ability to talk to the DraftSight team. We have the opportunity to discuss the software with the DraftSight team and the improvements that you guys have made, just the DraftSight team taking our feedback and other customers feedback and making that a reality. That is why we’re here.”

Knapheide Manufacturing Company is proud to have DraftSight as a partner and highly recommends it to anyone looking for a powerful, cost-effective, and sustainable 2D CAD software.

Download a free, 30-day trial of DraftSight Premium and try DraftSight for yourself. Don’t leave your money and time on the table when you can have more control in how you invest your resources. DraftSight is a comprehensive alternative for your design and drafting needs and then some.