“Contraptions Guy” Jeremy Cook and his Strandbeests

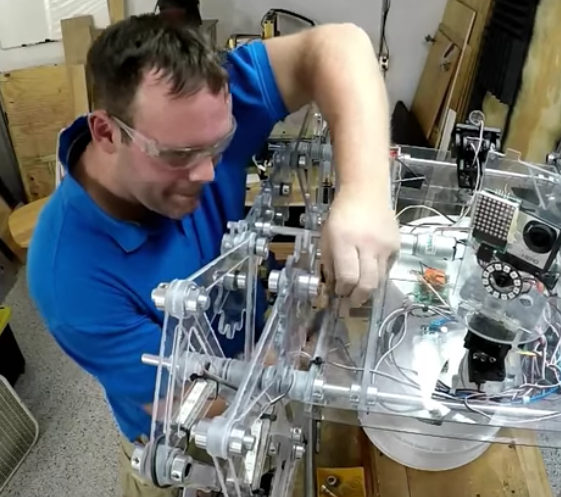

Jeremy Cook is a self-confessed “contraptions guy.” By day he is a consulting engineer who specializes in technical documentation. By nights and weekends he is a Maker. His shop is a menagerie of CNC machines, drill presses, Raspberry Pi microcomputers, a 3D printer, and more. He is a teacher at heart as well, sharing his work and love for his contraptions on YouTube (https://www.youtube.com/c/jeremyscook).

One of Jeremy’s favorite contraptions are Strandbeests, self-propelled multi-leg robotic walkers designed to walk on sandy beaches and other uneven terrain. He has become so well-known in the Strandbeest community to the point that he was featured on a Discovery channel program about his work.

CAD is an essential tool in Jeremy’s workflow. He works in both 2D and 3D, switching back and forth fluidly as the need or whim arises. Over the years he has used a variety of CAD products, and hasn’t really standardized on a single 3D application. But he has standardized on his 2D software of choice, DraftSight.

Many who are proficient in CAD say work speed is a major consideration, and prefer to get their idea down quickly in 2D, even if a 3D model is needed at the end of the project. Jeremy is one of those people. “While a graphical user interface is available and useful at times, it’s hard to beat the speed of typed commands,” he says. “As a longtime user of both 2D and 3D CAD packages, I love how well supported text commands are in DraftSight.”

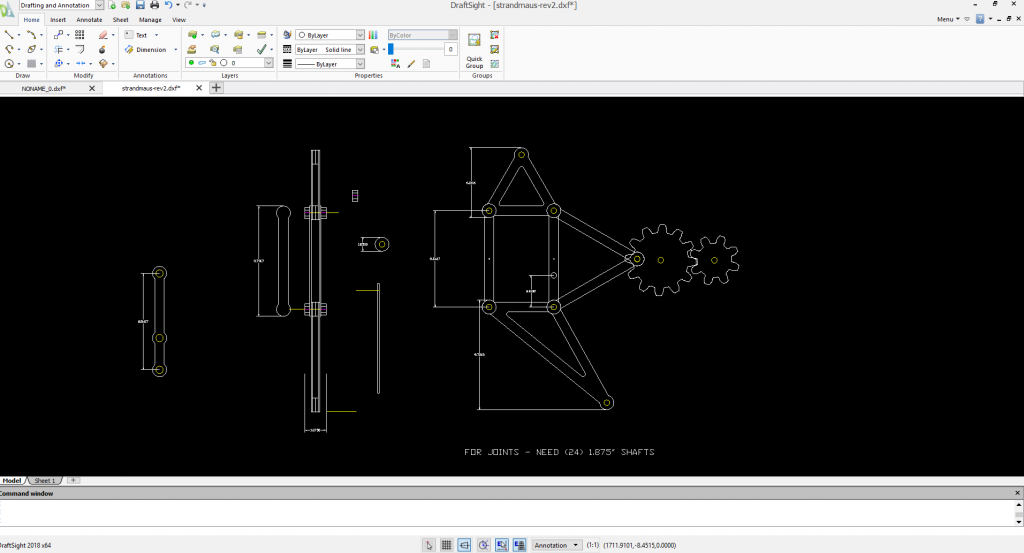

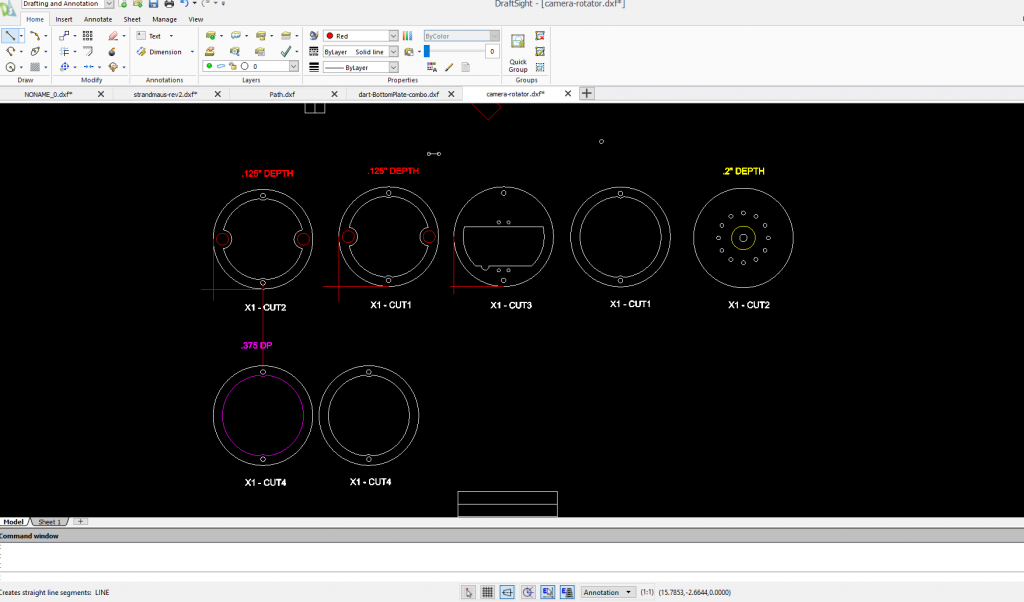

The most challenging part of a Strandbeest project is power transmission. “They walk like a tank,” he says. “Getting enough torque to turn the shaft is a big issue; alignment couplings are key.” For a recent project, he devised a central gear system. “All the gears I drew in DraftSight, then saved as DXF.”

Working with a variety of scale sizes is trivial for 2D CAD, a fact that comes in handy for Strandbeest design. “Some of these beasts are as big as a golf cart, and others only eight inches tall,” Jeremy says. Using the Scale command makes it easy to modify drawings for new CNC milling projects.

Jeremy does a lot of work with CNC, and uses 2D data to drive the machine. “DraftSight makes a good platform for working with CNC tools,” Jeremy says. “The fact that you can save drawings in DXF format is absolutely critical to transferring your designs to a CAM package and finally to the machine controller. I’m really excited about the auto-tracing function that’s scheduled to be released in the next version of DraftSight. This should make working with bitmapped drawings easier with my CNC router.”

Jeremy has a workflow when working on all his mechanical contraptions, not just the Strandbeests. “When making mechanical designs in 2D, I find it’s helpful to divide up the workspace into discrete segments for different iterations. Perhaps you’d like to go back to a few versions ago and examine how a feature came to be—just pan back in time and you can see your process from a few days, weeks, or even years ago.”

Making Strandbeests is about creating surprise and delight in those who see them for the first time. So it shouldn’t come as a surprise that Jeremy is a bit of a trickster as well. He has this “tip” for DraftSight users: “If you feel like playing a joke on coworkers “mbuttonpan” and “zoomfactor” are quite useful to cause some minor mayhem.”