HeatTek Inc. – Supporting Growth with SOLIDWORKS and DraftSight

In today’s world of 3D parts and assemblies, SOLIDWORKS® 3D design software helps customers quickly respond to customer demands and shorter delivery lead times by increasing efficiency and throughput for 3D needs, such as large-assembly design. But 2D drawings are still an important part of bringing products to life.

Read the full HeatTek, Inc. Case Study

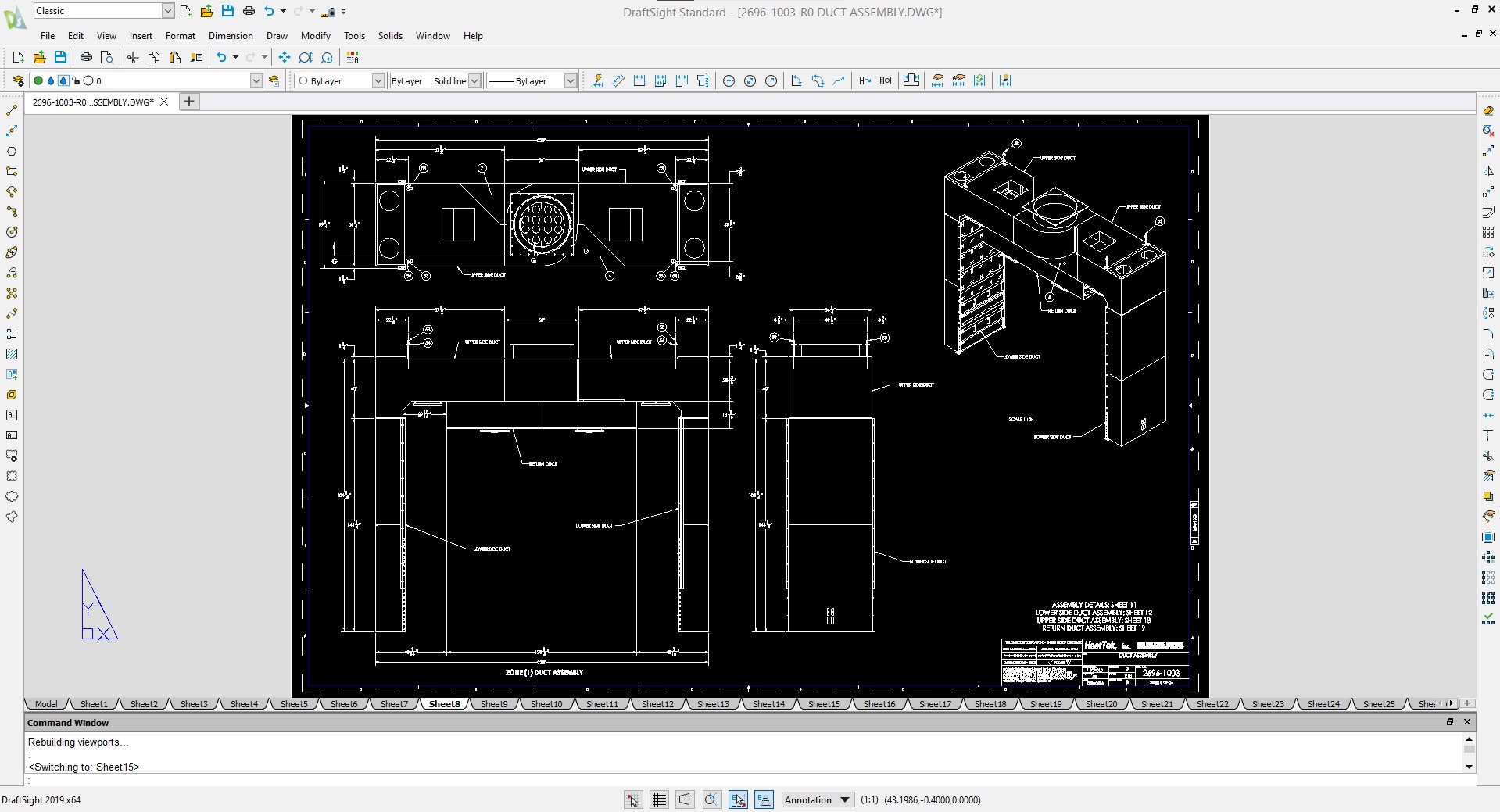

2D drawings are still needed for 2D tasks, including improving user understanding of design details, accessing legacy drawings and data, and creating simple layouts and schematics. 2D drawings distill rich 3D models into a simplified perspective where selected key information, such as dimensions and tolerances, are presented concisely for important decisions. 2D drawings are also helpful for supporting functions outside of engineering and design. Plus, on the many occasions where hard copies are preferred, 2D drawings still come in very handy.

Optimizing 2D and 3D CAD Workflows

Many organizations are optimizing 2D and 3D CAD workflows with DraftSight and SOLIDWORKS. DraftSight is fully interoperable with SOLIDWORKS, making it seamless to go back and forth between the two applications. Even when the majority of design and engineering work is done in 3D using SOLIDWORKS software, companies still have needs that are better addressed with 2D tools.

Real-World Example – HeatTek, Inc.

HeatTek, Inc. is a global thermal equipment supplier, based in Ixonia, Wisconsin, USA, that provides customize oven, furnace, and heat treatment equipment designs. When HeatTek management decided to move to SOLIDWORKS® 3D design software in 2014 to satisfy customer demand for shorter delivery lead times, the company discovered that it still needed a robust 2D design tool.

HeatTek chose DraftSight because the software enables the company to handle simple layouts and schematics, access its legacy CAD designs and data, and support functions outside of engineering and design at significantly less cost.

How HeatTek succeeds with DraftSight Professional

- Shortened product development cycles

- Compressed customer delivery lead times

- Reduced cost of 2D design

- Supported growth associated with tripling of revenue

Greater Access to Data

“When we switched to SOLIDWORKS 3D design, which everyone we spoke with recommended over Autodesk Inventor, we still needed an AutoCAD-compatible 2D solution for a couple reasons,” says HeatTek, Inc. Project Engineer II Mike Galligan. “There are other departments and personnel who don’t necessarily need a 3D CAD license but still need access to design information, and we often review our legacy designs when beginning a similar project. Also, our fabricators need DWG files from us to manufacture components and assemblies, and while we can create those in SOLIDWORKS, others often need to access them,” Galligan recalls.

For many organizations using both 2D design and 3D design software, DraftSight provides greater access to design drawings and data among other departments, allowing them to further contribute to the company’s productivity gains.

“Our management was proactive in moving to 3D design but recognized that we couldn’t purchase a SOLIDWORKS license for everyone who needs access to drawings,” Galligan points out. “For example, our Field Service personnel all have laptops and can access drawings using DraftSight when they are on a customer site installing or servicing equipment.

“Our Sales and Applications Department is saving a lot of time using DraftSight, which our Spare Parts, Production Control, and Purchasing groups also use. Our shop personnel all have eDrawings® Viewers, which they and others use when they need to see something in 3D,” Galligan says. “In short, Engineering uses SOLIDWORKS 3D and everyone else can access drawings and information using DraftSight.”

Interested in learning more? Read the full HeatTek, Inc. Case Study

What can DraftSight do to help keep your design projects on track? Learn more and try DraftSight for free.